Novel Engineers uses state-of-the-art 3D printing (also known as Additive Manufacturing) technology to generate prototypes in a matter of hours. These prototypes are completely functional and allow testing and design adjustments to occur well before full production. This reduces design time and avoids costly changes in later phases.

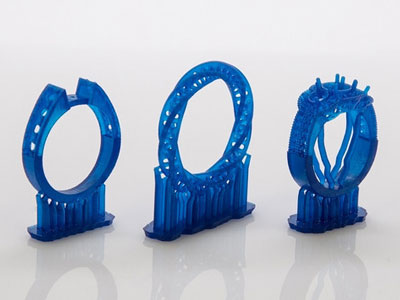

We take a CAD drawing file and convert it to a format accepted (.STL) by the 3D Printer. The Printer applies a thin layer liquid polymer and uses intense ultra-violet light to solidify the liquid polymer and fuse it to the layer below. The layering process is repeated hundreds of times until the final product is complete.

If you only require a few parts (1 to 100), our 3D printing capability supports production runs for small-volume orders. 3D printing is desired for small production runs due to the high front-end costs associated with tool making for plastic injection molding manufacturing.

If you are an entrepreneur with a design and need to create some samples for demonstration, let us work with you to create what you need test the market.

(1) HP Make 5200 series MJF technology material : PA 12 ( Nylon)

(2) Form Labs 3L SLA technology wide range of Rigid, Flexible, Transparent & Medical grade.

(3) Mark Forged FDM Technologies Composite materials

(4) EOS /Markforged DLMS /ADAM technologies Metal 3d printing