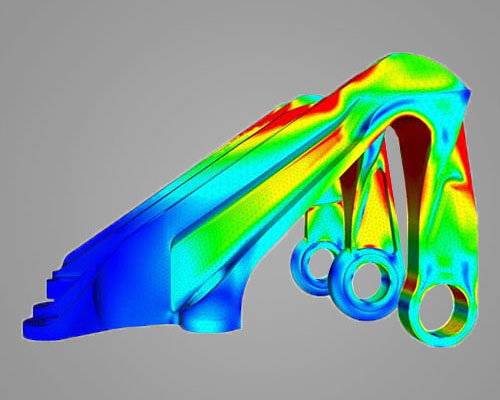

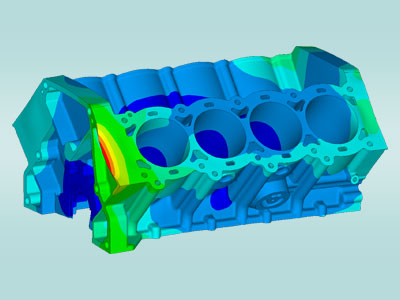

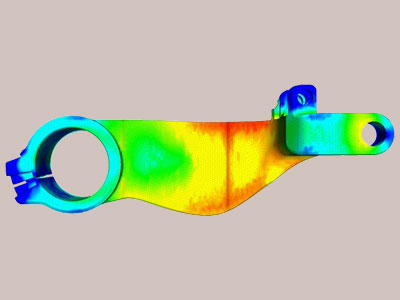

Finite element (FEA) methods along with structural analysis or stress analysis are commonly used in many industries, especially during complex stress problems. Stress analysis can be applied extensively in several manufacturing scenarios where safety factors have to be determined or cost, material, weight, strength, etc., have to be optimized. The analysis is also a cost-effective alternative to experimental testing.

Working with firms across the globe, our team of engineers, analysts, and quality systems work on advanced analysis tools to help you make your product design flawless. Our finite element analysis services cover -

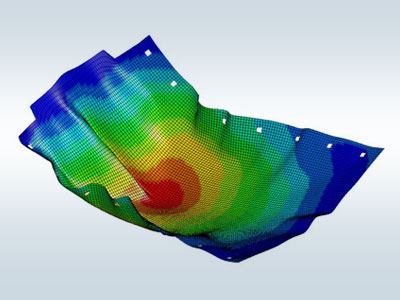

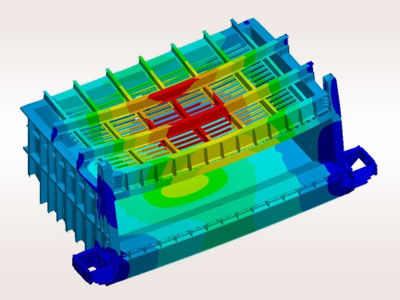

We have the required skills and expertise to provide you with top quality structural analysis services. We leverage finite element computer simulation to perform analysis of various products and processes. This is highly beneficial while optimizing material, strength, cost, weight, etc.

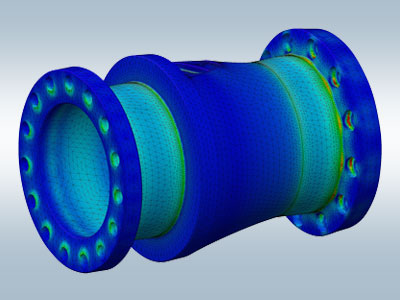

Our team of engineers can simulate incompressible and compressible fluids inside ducts, pipes, impellers, etc.

Novel Engineershas the required tools and skills to provide clients with static and dynamic analysis which helps them avoid any kind of machine faults.

We have some of the most skilled engineers who can help you with complex fluid-structure interaction. CFD and large eddy simulations provide you with deep insight into vortex shedding, shear stresses, and any other turbulence within the design.

We have the required skills to leverage the best design optimization tools which will help in determining the best materials, weights, and dimensions for your design.

We provide our clients with quality composite analysis of the materials used in the design. Reliability is a key component of any design and our services ensure reliability in the long run.

We leverage thermal analysis to ensure uniform temperature distribution in a certain component. Our services ensure that the component behaves in the desired way when subjected to internal and external sources of heat.

Our mechanical engineering team at Novel Engineerscan provide you with the optimization and improvement of designs of multi-bar linkages and other components.

We leverage the benefits of stress analysis to determine and predict fatigue and any possibility of fractures through simulations. This helps in determining the durability of the components when they are subjected to different stresses.

Apart from the above-mentioned services, our team of mechanical engineers at FWS has the skills to provide the following services as well -